Droplet Evaporation Condensation Frosting

Frosting

Overview

Frost formation on surfaces generally causes unwanted consequences in various fields from the safety of aircraft, to efficiency of energy transportation system such as refrigeration, air-conditioning (HVAC), and food preservation, telecommunication equipment, wind turbine. These aspects take place because frost layer makes a porous media, which has such insulation and air blocking effects. The process of frosting can be divided into three stage by its specific behavior: First regime is condensation stage. The second regime is the appearance of ice nucleation and frost propagation stage. Third regime is frost growth stage. We investigated the whole frosting process.

Frosting on super-hydrophobic surface

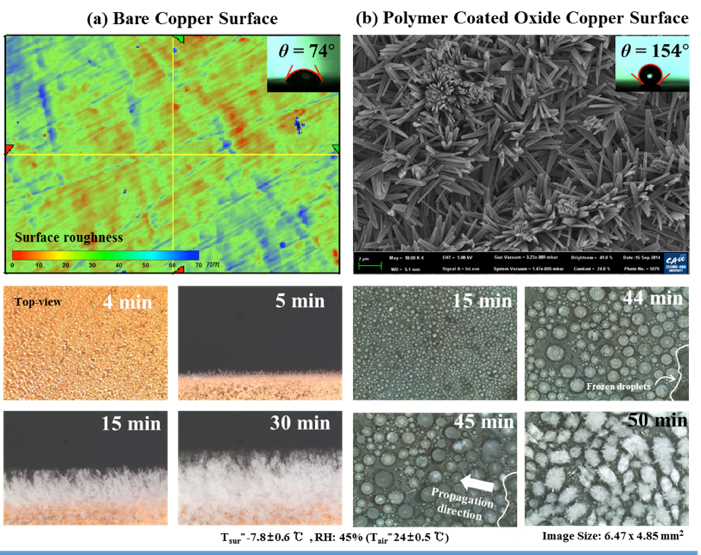

Many researchers investigated the frosting characteristics and they suggested useful correlation using several factors such as surface temperature, air temperature and humidity, stream flow, and surface geometry etc. Meanwhile, the surface wettability has been regarded as one of the important factors substantially affecting the frosting characteristics especially in ice nucleation stage. Frosting was delayed on the hydrophobic surface and it is expected that hydrophobic surface can solve several technical problems. Many researches was conducted to investigate the effect of wettability on frosting characteristics. We also investigated the frosting characteristics affected by the surface wettability. Delayed icing and frost propagation in the early stage was observed with different surface wettability. In addition, the mechanism of delayed icing and frost propagation on hydrophobic surface was analyzed in point view of thermodynamics.

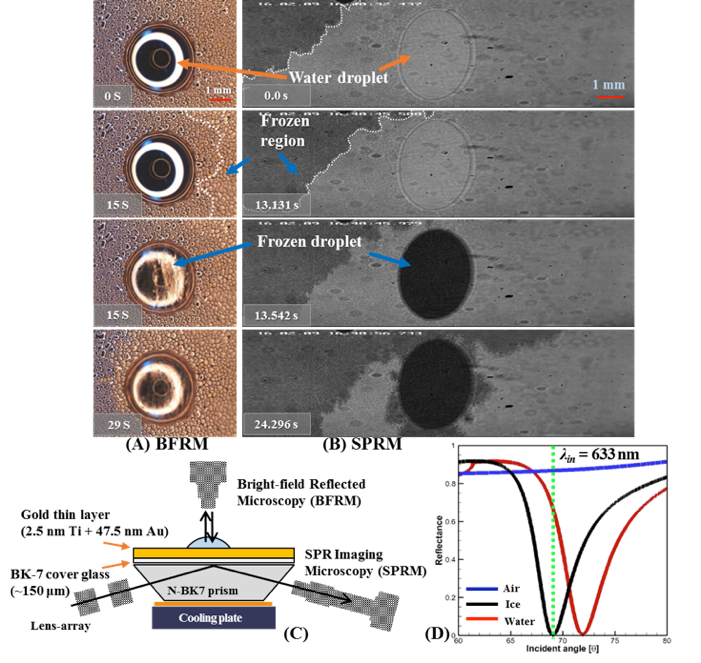

Visualization of frosting using SPR imaging microscopy

Many researchers investigated frosting phenomenon with help of visualization technology. For example, the frosting process is usually captured using a bright-field reflected microscopy (BFRM) placed above the opaque metal surfaces. SPR microscopy can characterize the properties of the thin region within a thickness of 100~600 nm by measuring the changes in the refractive index (RI) of test media. The SPR has advantages to conduct in-situ measurement and provide the insight of dynamic nature of thin frost layer. In this study, in order to observe and gain insight into the frost thin layer during frosting process, we have utilized SPR imaging method.

The MTEL has studied the condensation frosting characteristics on the various surface having different wettability (hydrophilic, θ < 90deg, hydrophobic, 90deg < θ < 150deg, and superhydrophobic, 150deg < θ)

Superhydrophobic, 150deg < θ Hydrophobic, 90deg < θ < 150deg Hydrophilic, θ < 90deg

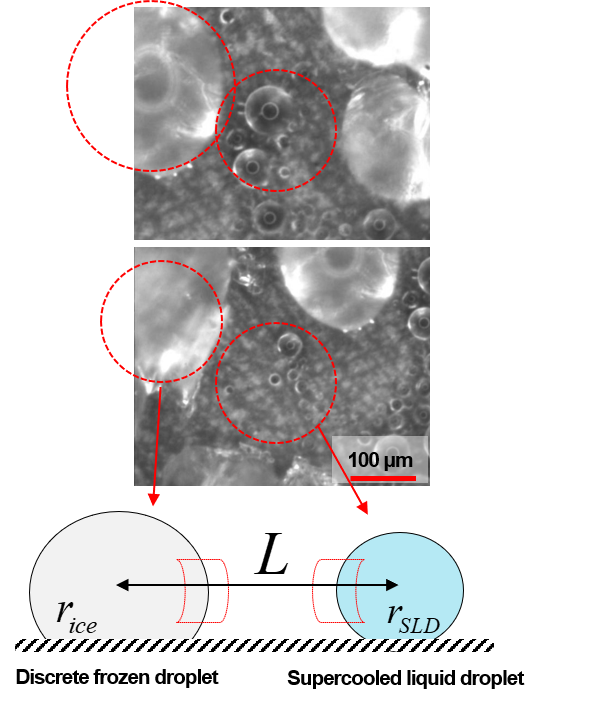

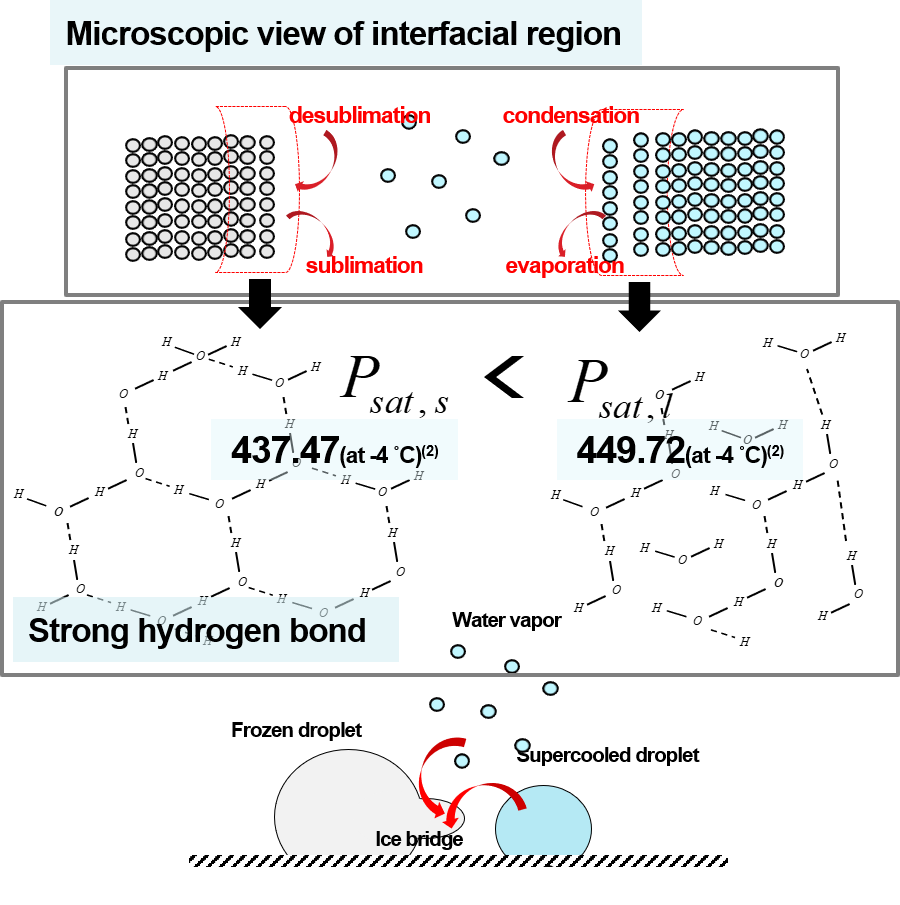

It was found that even if the substrate remained at a subfreezing temperature, the spontaneous freezing of supercooled condensates did not occur because of the free energy barrier of ice embryo at the interface of the substrate-supercooled droplet. The onset of condensate freezing was also triggered by probabilistic ice nucleation. In particular, the dely of the onset time of freezing was found for the nanostructured superhydrophobic surface and substantially dependent on the coolant temperature. Moreover, it observed the presence of an interdroplet ice bridging between a frozen droplet and neighboring supercooled droplets

Ice propagation process on the superhydrophobic surface

Related published articles are as follows:

- C. H. Jeong, Seong Hyuk Lee, Condensation frosting characteristics of SAM coated nanostructured superhydrophobic surface, International Journal of Air-Conditioning and Refrigeration, Vol. 26, No.1, 2018.