Droplet Evaporation Condensation Frosting

Condensation

Overview

Condensation means the phase change at the gas state when the steam temperature decreases below the saturation temperature. Condensation is an important heat and mass transfer method that is used in all different industrial areas ranging from large power generation and chemical plants to heat exchanger, automobile’s air conditioning system, micro cooling system and electronic goods. Additionally, application areas for the condensation heat transfer is expanding to the water harvesting from fog these days for the areas that lack water whereas it was used traditionally for seawater desalination.

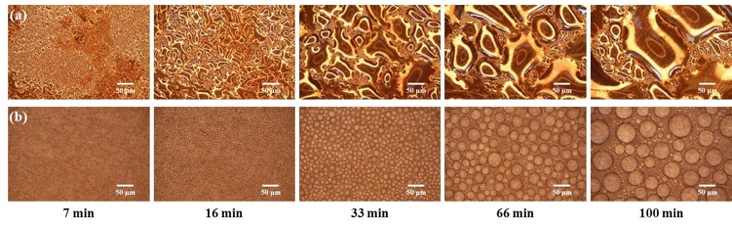

Condensation that occurs on solid surface is called surface condensation, and it is divided into filmwise condensation (FWC) and dropwise condensation (DWC). During the filmwise condensation process, liquid film that covers the condensed surface gets stalled easily, and becomes thicker with time since removal is not effective. Likewise, since liquid film that is generated on the surface reacts as thermal resistance, heat transfer from the solid surface is disturbed. By contrast, droplets of diverse size get formed on the condensed surface and get removed due to self-weight, exposing new surface which in turn increases heat transfer in case of dropwise condensation. Moreover, it is know that the heat transfer coefficient is higher in case of the dropwise condensation compared to the filmwise condensation.

The comprehension of the integrated droplet growth behavior through the single droplet growth and coalescence among droplets during dropwise condensation is essential in order to improve the heat transfer performance of the heat exchanger that is used in industries. Analysis on the effect of these droplet growth characteristics on the overall condensation heat transfer is required.

Therefore, the purpose of this research is to develop dropwise condensation heat transfer model following the droplet growth after conducting the research on the liquid droplet growth mechanism on the chemically textured copper surface.