Visualization & Measurement

Evaporating Thin film of DI-water droplet

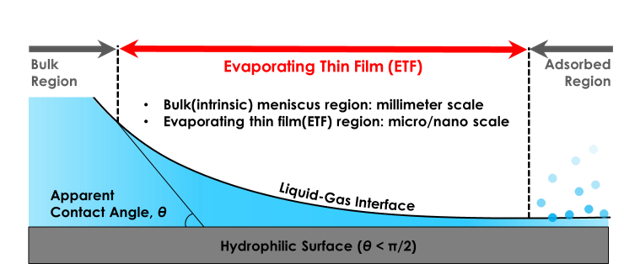

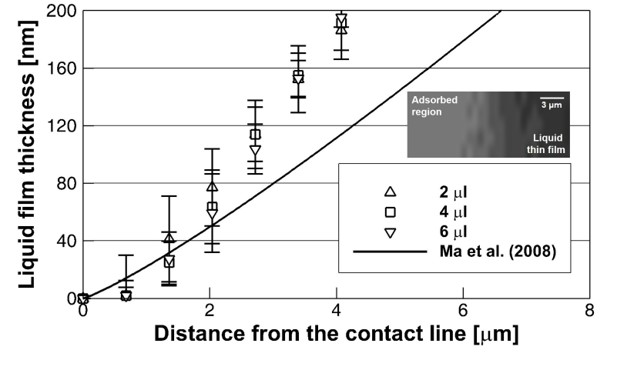

We visualize a contact line region including evaporating thin film (ETF) and suggest a new approach for estimating a finite evaporation flux based on a diffusion-limited model. The profiles that cover part of the ETF and the adsorbed film were obtained using the surface plasmon resonance imaging (SPRi) technique. The width and thickness of the contact line region were determined.

Schematic of contact line region Evaporating thin film profile

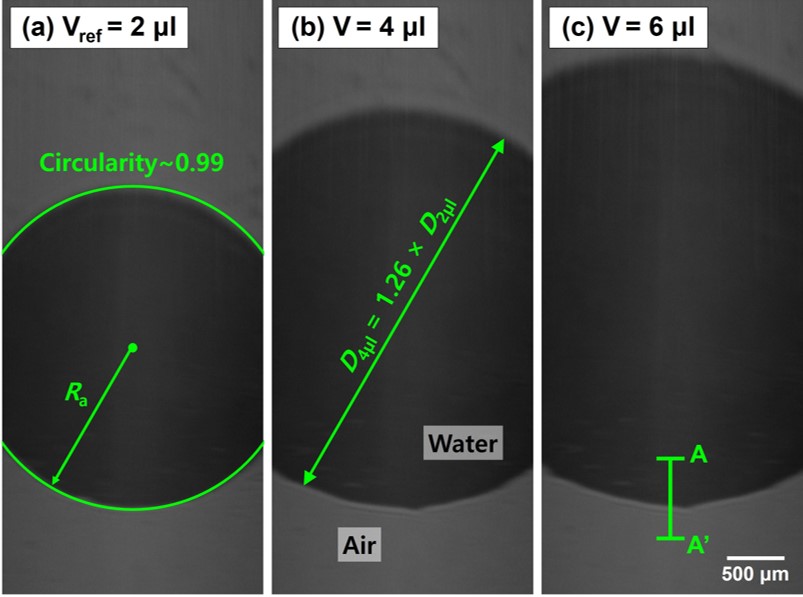

Surface plasmon resonance image of droplet

- Evaporating thin film(ETF) visualization of droplet at contact line region

- Submicron scale film profile measurement during droplet evaporation

- Proposed finite evaporation flux based on a diffusion-limited model using measured ETF profile

Related published articles are as follows:

- Dae Yun Kim, Chan Ho Jeong, Hyung Ju Lee, Chang Kyoung Choi, and Seong Hyuk Lee, Modeling of the finite boundary limit of evaporation flux in the contact line region using the surface plasmon resonance imaging, International Communications in Heat and Mass Transfer, Vol. 116. July, 2020.

Evaporating Thin film (Microscopic view)

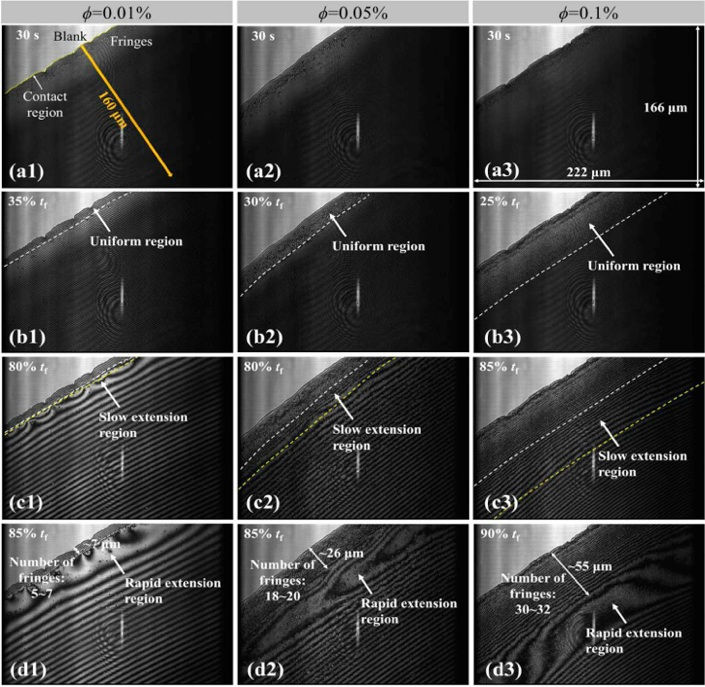

During the evaporation of a droplet, there exists an evaporating thin layer that is difficult to visualize because of optical restrictions. So, we used the confocal microscope that can provide an improved signal-to-noise focal plane imaging over traditional optical microscopy while simultaneously serving as an interferometer when imaging thin liquid films. The spatial distribution of the evaporating thin layer thickness was determined from the interferometric fringe analysis. We noted that the nanoparticle bank formed near the contact line region substantially affects the rate of change in the evaporating thin layer thickness that increases with the nanoparticle concentration.

Related published articles are as follows:

- Dong Hwan Shin, Jeffrey S. Allen, Chang Kyoung Choi and Seong Hyuk Lee, Visualization of an evaporating thin layer during the evaporation of a nanofluid droplet, Langmuir, Vol. 31, No. 4, pp. 1237-1241.

Droplet impingement

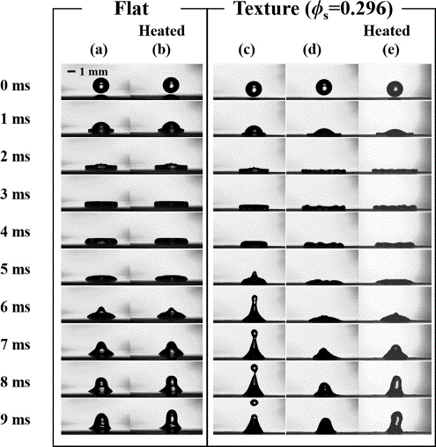

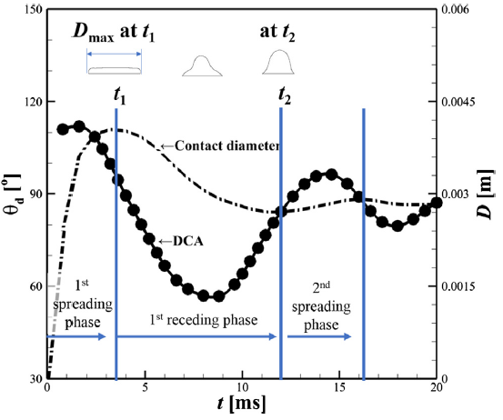

We investigates the temporal evolution of the dynamic contact angle (DCA) of a droplet impinging on the flat and textured surfaces. The hole-patterned textured surfaces are manufactured by using a drilling machine with two texture area fractions to examine the variation in DCA according to the Weber number, surface temperature, and texture area fraction.

Sequential images of impinging droplet Dynamic contact angle and contact diameter

- Static and dynamic characteristics of water droplet impacting on hydrophilic and hydrophobic substrate

- Visualization of droplet impact on the surface using high-speed camera

- Dynamic contact angle and contact diameter analysis with different operating conditions

Related published articles are as follows:

- Joo Hyun Moon, Sang Min Lee, Chang Kyoung Choi, and Seong Hyuk Lee*, Dynamic Characteristics of Droplet Impingement on Microscale Hole-Patterned Surfaces with Anodization, International Communications in Heat and Mass Transfer, Vol. 124, pp.105260.

- Joo Hyun Moon, Minhaeng Cho, Seong Hyuk Lee,Dynamic contact angle and liquid displacement of a droplet impinging on heated textured surfaces, Experimental Thermal and Fluid Science, Vol. 101, pp. 128-135. 2019.

- Joo Hyun Moon, Chang Kyoung Choi, Jeffrey S. Allen, Seong Hyuk Lee, Observation of a mixed regime for an impinging droplet on a sessile droplet, International Journal of Heat and Mass Transfer, Vol. 127, pp. 130-135. 2018.

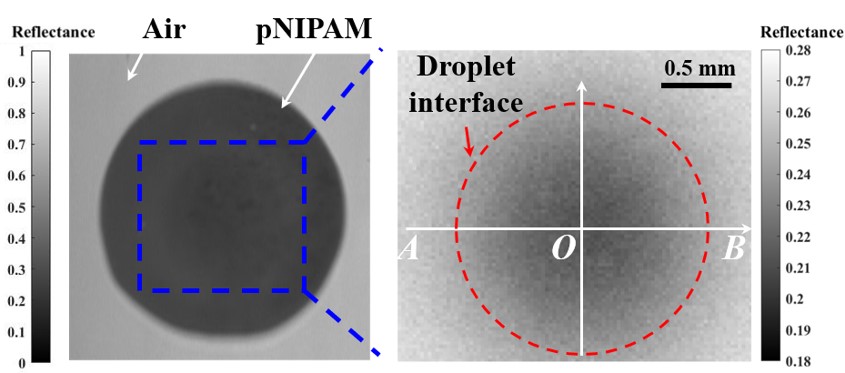

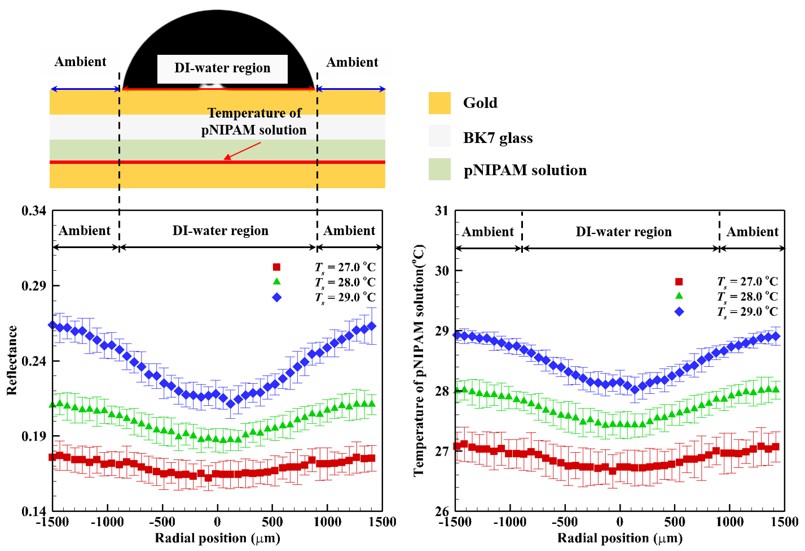

Solid-liquid interface temperature measurement method using thermoresponsive polymer

We measure the solid–liquid interface temperature of an evaporating droplet on a heated surface using a thermoresponsive polymer. Poly(N-isopropylacrylamide) (pNIPAM) was used owing to its sensitive optical and mechanical properties to the temperature. We also measured the refractive index variation of the pNIPAM solution by using the surface plasmon resonance imaging (SPRi). In particular, we proposed a new method to measure the solid–liquid interface temperature using the correlation among reflectance, refractive index, and temperature.

SPRi of pNIPAM solution after droplet deposition

Reflectance of pNIPAM solution and calculated temperature

A novel temperature measurement method using pNIPAM solution and surface plasmon resonance imaging

A novel temperature measurement method using pNIPAM solution and surface plasmon resonance imaging- Obtained relations between the reflectance, refractive index, and temperature of pNIPAM solution

- Solid-liquid interface temperature on multilayer film is calculated through proposed temperature measurement method

Related published articles are as follows:

- Hyung Ju Lee, Chan Ho Jeong, Dae Yun Kim, Chang Kyoung Choi, and Seong Hyuk Lee, A novel method of solid-liquid interface temperature measurement of evaporating droplet using thermoresponsive polymer aqueous solution, Applied sciences, Vol. 11, pp. 3379.